THE BARISTA’S NEMESIS: WHEN WEATHER WREAKS HAVOC ON YOUR GRIND

Ever watched a seasoned barista crack it at the sight of an incoming storm front? There’s a good reason for that. In the high-precision world of specialty coffee, Mother Nature can really mess things up.

When baristas talk about “dialing in,” they’re engaging in a delicate dance of adjustments on the grinder to achieve extraction perfection. But what happens when the weather refuses to cooperate? My story of Sam’s Monday morning meltdown at Café Nomad (I totally made this name up) illustrates a phenomenon that haunts cafés worldwide but rarely gets discussed outside professional circles.

THE MORNING RUSH DISASTER

It’s Monday morning, and Sam, the opening barista at Café Nomad (the name’s growing on me), turns on the grinder to start dialling in the espresso. Yesterday, it was hot and dry (38°C), but overnight, the temperature dropped to 18°C with rain. Sam loads the portafilter and presses the grind button, expecting the usual 20 gram dose; but only 12 grams comes out.

Sam’s first thought? “Who messed with the grinder!?”

Frustrated, Sam checks the grind setting. It hasn’t changed. He tries dosing again, still underdosing. He opens the hopper, and the beans look fine. Confused, he calls the manager, Mia.

DIAGNOSING THE PROBLEM

Mia arrives and starts troubleshooting. She checks three things:

- Grind Consistency – The coffee is coming out in clumps, a sign of moisture buildup.

- Grinder Retention – She notices coffee grounds sticking inside the chute and burr chamber.

- Weather Conditions – She remembers that last night’s rain increased humidity, likely making the beans slightly denser and causing retention issues.

She also asks, “When was the last time we cleaned the grinder?” Sam hesitates, neither of them can remember.

THE SCIENCE BEHIND THE STRUGGLE

“What many baristas don’t realize is that coffee beans are hygroscopic, they absorb moisture from the air,” explains Mel our head trainer. “A sudden increase in humidity can cause beans to absorb 3-5% of their weight in moisture within 24 hours.”

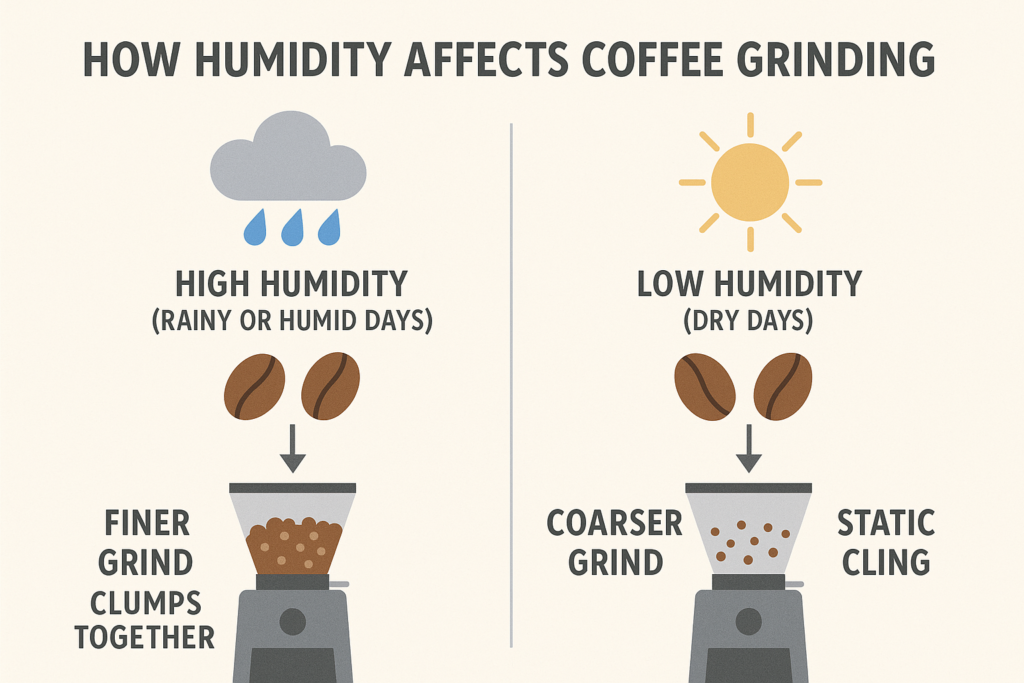

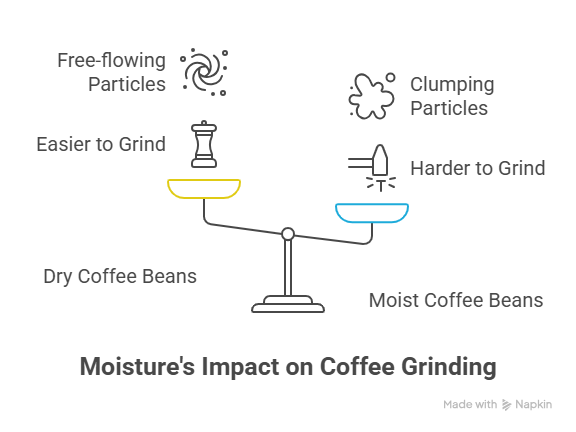

This moisture absorption affects grinding in two critical ways:

- Bean Density Changes – As beans absorb moisture, they become denser and more difficult to grind, requiring more force to break them down.

- Particle Cohesion – Moisture creates electrostatic charges that cause ground particles to stick together and to metal surfaces inside the grinder.

According to a 2023 study published in the Journal of Coffee Research, a 20% rise in relative humidity can reduce grinder output by up to 40% if no adjustments are made.

THE FIX

Mia follows a methodical approach to solve the problem:

- Purge the Grinder – Mia runs some beans through to clear out any retained coffee. Still, the dosing issue persists.

- Run Grinder Cleaning Pellets – She runs a capful of pellets through the grinder to clear out oil buildup and old, compacted grounds.

- Purge Fresh Beans – She loads fresh beans and doses again. The problem improves immediately, with 18 grams now dosing instead of 12 grams.

- Adjust Grind Slightly Coarser – Since the beans absorbed moisture overnight, she slightly coarsens the grind to get back to the 20 gram target dose.

“These weather-related adjustments aren’t optional in specialty coffee,” says Mel, Head Barista Trainer The HG Coffee School. “They’re as fundamental as knowing your extraction ratios.”

QUICK RESPONSE PROTOCOL FOR WEATHER SHIFTS

| Weather Change | Symptoms | Immediate Response | Preventive Measures |

| Sudden increase in humidity | Underdosing, clumping grounds | Coarsen grind, clean retention points | Store beans in airtight containers |

| Rapid decrease in humidity | Overdosing, faster flow rate | Tighten grind, check extraction time | Use two-way humidity control packets |

| Temperature spike | Increased oil release, retention | Clean chutes and burrs | Keep beans in temperature-stable location |

| Seasonal transition | Gradual changes in consistency | Daily recalibration | Adjust protocols seasonally |

REGIONAL CHALLENGES

In the Adelaide Hills for example, our foggy mornings mean we start with a coarser grind setting than most would expect. By midday, as things dry out, we’re often tightening the grind incrementally. Meanwhile, the Adelaide CBD location deal with extreme dryness, requiring different storage solutions altogether.

In contrast, a café in Melbourne during our winter, we sometimes adjust grind settings eight times in a single day. We’ve implemented a weather log alongside our dial-in notes to track patterns.

The Takeaway

Mia explains to Sam:

- The sudden weather change made the beans denser, slowing down grinding.

- Moisture buildup and stale coffee retention were choking the grinder.

- Oil buildup from weeks of no cleaning made the grinder less efficient.

They decide to schedule grinder cleaning every first Monday of the month and stick a small reminder label on the machine. Additionally, they implement a new protocol:

- Check local weather forecast during closing shift

- Note significant changes in the handover log

- Adjust opening procedures accordingly

Understanding the relationship between weather and grinding performance isn’t just coffee trivia, it’s essential knowledge for consistent quality. By implementing regular cleaning protocols and staying attuned to atmospheric shifts, cafés can minimize the impact of these variables. The cafes adjust their workflow based on weather forecasts, treating each climate change as seriously as they would a broken machine.

Remember: in specialty coffee, precision isn’t just about having expensive equipment, it’s about adapting to invisible factors that influence every cup. As Sam learned through that frustrating Monday morning, sometimes the difference between a perfect espresso and wasted coffee isn’t skill or equipment quality, but simply recognizing when Mother Nature has changed the rules of the game overnight.